Instrumentation

The Instrumentation Academy strives to deliver world-class training programmes in Instrumentation and Control. It offers well-structured learning programmes covering Field Instrumentation, Quality Measuring Instrument, Instrumented Safeguarding System, Control System and Liquid & Gas Metering for Oil & Gas and other industries for technicians and engineers.

As an internationally-recognised training centre, INSTEP is equipped with the state-of-the-art facilities to meet the demands of industrial occupational standard in producing skilled and competent manpower.

Our instructors are BTEC Certified Assessors and/or Verifiers by Pearson Education Limited, UK and they are currently moving towards obtaining Australian Certificate IV in training and assessment.

Instrumentation

The Instrumentation Academy strives to deliver world-class training programmes in Instrumentation and Control. It offers well-structured learning programmes covering Field Instrumentation, Quality Measuring Instrument, Instrumented Safeguarding System, Control System and Liquid & Gas Metering for Oil & Gas and other industries for technicians and engineers.

As an internationally-recognised training centre, INSTEP is equipped with the state-of-the-art facilities to meet the demands of industrial occupational standard in producing skilled and competent manpower.

Our instructors are BTEC Certified Assessors and/or Verifiers by Pearson Education Limited, UK and they are currently moving towards obtaining Australian Certificate IV in training and assessment.

Liquid and Gas Metering

This programme provides basic understanding of liquid & gas metering system and its applications based on several metering installations in oil & gas industry.

It mainly focuses on metering operation practices in petroleum industry with emphasis on custody metering.

At the end of this programme, participant will be able to:

- Explain the working principle of the volumetric flowmeter

- Perform metering equipment maintenance and validation

- Perform volumetric flowmeter proving

Introduction to the Distributed Control System (DCS) Operation - Yokogama CS3000 for Process Operator

This programme is designed to develop participants’ knowledge, skills and competency to perform the roles of a process operator involving Distributed Control System (DCS) Operation for Yokogama CS3000.

At the end of this programme, participant will be able to:

- Identify the major components of DCS System Architecture

- Describe and operate the HIS essential functions and interpret the system messages

- Describe the basic control loop and control strategy used in CS3000

- Describe and interpret the process & system alarm in CS3000

- Describe the trend functionality and structure of report in CS3000

Certified Personnel for Metering Validation and Calibration Competency Programme

This is a 5-days competency programme which provides knowledge and skills to participants to become certified personnel for metering validation and calibration.

At the end of this programme, participant will be able to:

- Perform metering validation and calibration activities in accordance with the procedures and standards

- Be certified competent personnel who perform metering validation and calibration activities

Instrument Installation and Maintenance

This is a 3-days programme which provides basic understanding to participants about instrument installation and maintenance.

At the end of this programme, participant will be able to:

- Describe various aspect and drawings of Instrument Installation

- Explain the basic knowledge of cabling and tubing works

- Aware of common mistakes made during installation & maintenance

Liquid Metering Training Skid

This facility is equipped with various types of flowmeters such as Ultrasonic, Coriolis, and Turbine Flowmeter which are completed with prover, station computer and flow computer that will enable our learners to develop and enhance their knowledge and skills in operation of metering skid, validation of field instruments, and meter proving.

Distributed Control System (DCS) Lab

This facility is equipped with Honeywell and Yokogawa DCS System which are integrated with process mini plants.

It enables the learners to develop and enhance their knowledge and skills in performing operation and control of the process mini plants, as well as maintenance and engineering activities on the control system.

Additionally, this facility is also equipped with Operator Training Simulator (OTS) which enables our learners to develop skills as a Panel Operator.

Process Control Lab

This facility is equipped with various models of mini plants that utilise air and water as the process medium. They can be integrated to form more complex plants. The Process Plants can be controlled either via Local Controller or DCS Programmable Logic Controller (PLC).

These enable our learners to develop and enhance their knowledge and skills in performing safe operation and control of the process mini plants, installation, and maintenance of field instruments.

Control Valve Workshop

This facility is equipped with various types of Control Valves ranging from pneumatic to SMART type Control Valve, which are completed with test and calibration equipment that will enable the learners to develop and enhance their knowledge and skills in performing testing, maintenance, and calibration of Control Valve.

Analyser Lab

This facility is equipped with various types of online analysers, Gas Chromatograph and Vibration Monitoring System which enable the learners to develop and enhance their knowledge and skills in performing installation, maintenance, and calibration of Quality Measuring Instrument and Condition Monitoring System.

Instrumented Safeguarding System Lab

This facility is equipped with Safety Instrumented System (SIS) and Fire and Gas System (FGS). These systems are fully integrated with DCS, Human Machine Interface (HMI), Motor Control Circuit (MCC), and others that replicate the real oil and gas plant/platform systems architecture and technologies. Both systems use TRICON TMR and Honeywell Safety Manager QMR safety programmable logic controller as the logic solver. These safety programmable logic controllers are linked to DCS and HMI via MODBUS communications in both serial and TCP/IP.

SIS is equipped with various types of sensors and final elements that are configured to execute the safety function of water level and flow in mini plant and SIS training skid. FGS, on the other hand, also uses various types of fire and gas detectors and actuators. All fire and gas detectors are fully equipped with testing and calibration tools.

These facilities enable our learners to develop and enhance their knowledge and skills in performing safe operation, maintenance, and calibration of SIS and FGS.

Measurement Lab

This facility is equipped with the field instruments such as sensors, transmitters, switches and other calibration tools which enable the learners to develop and enhance their knowledge and skills in performing installation, maintenance, and calibration of process measuring instrument.

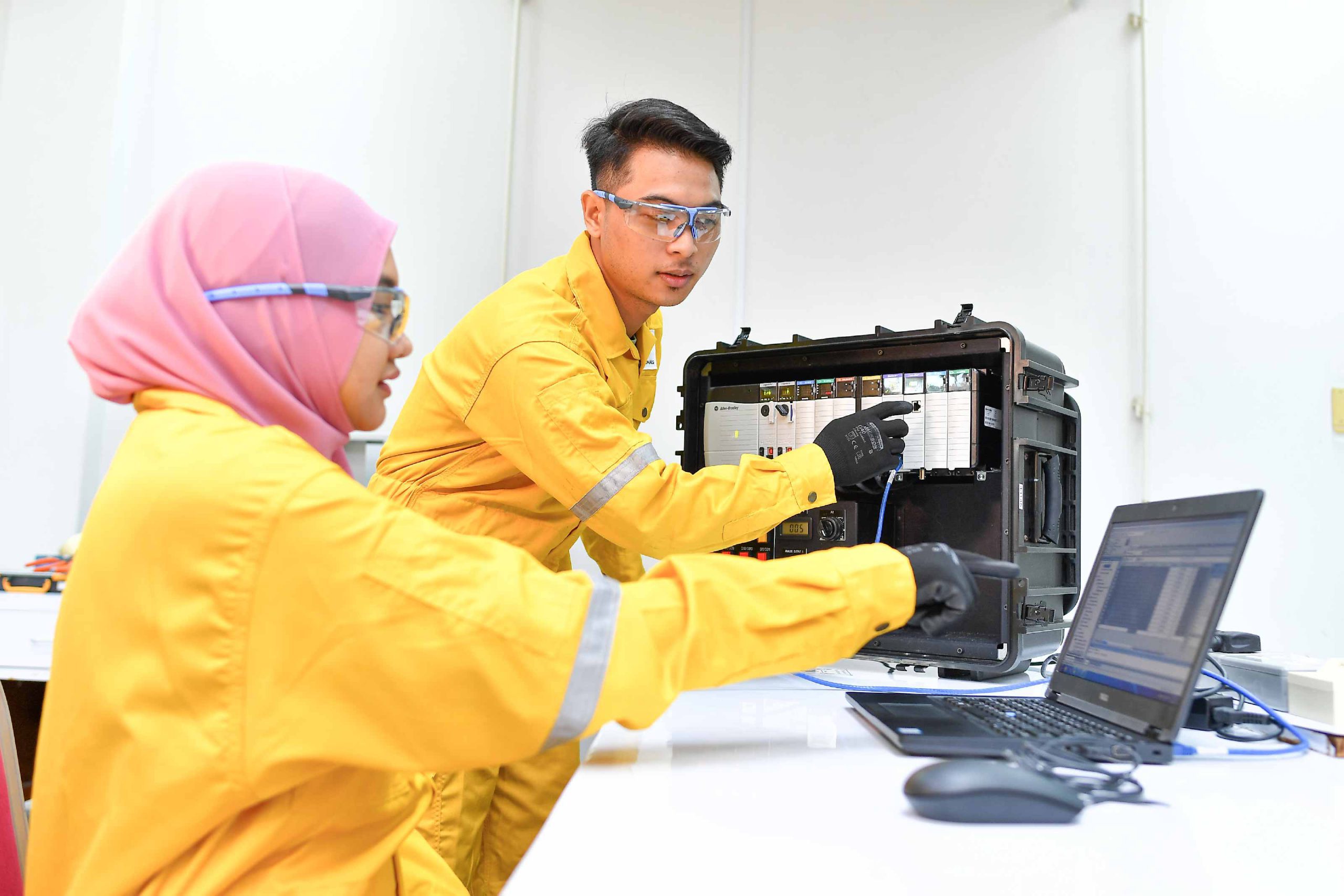

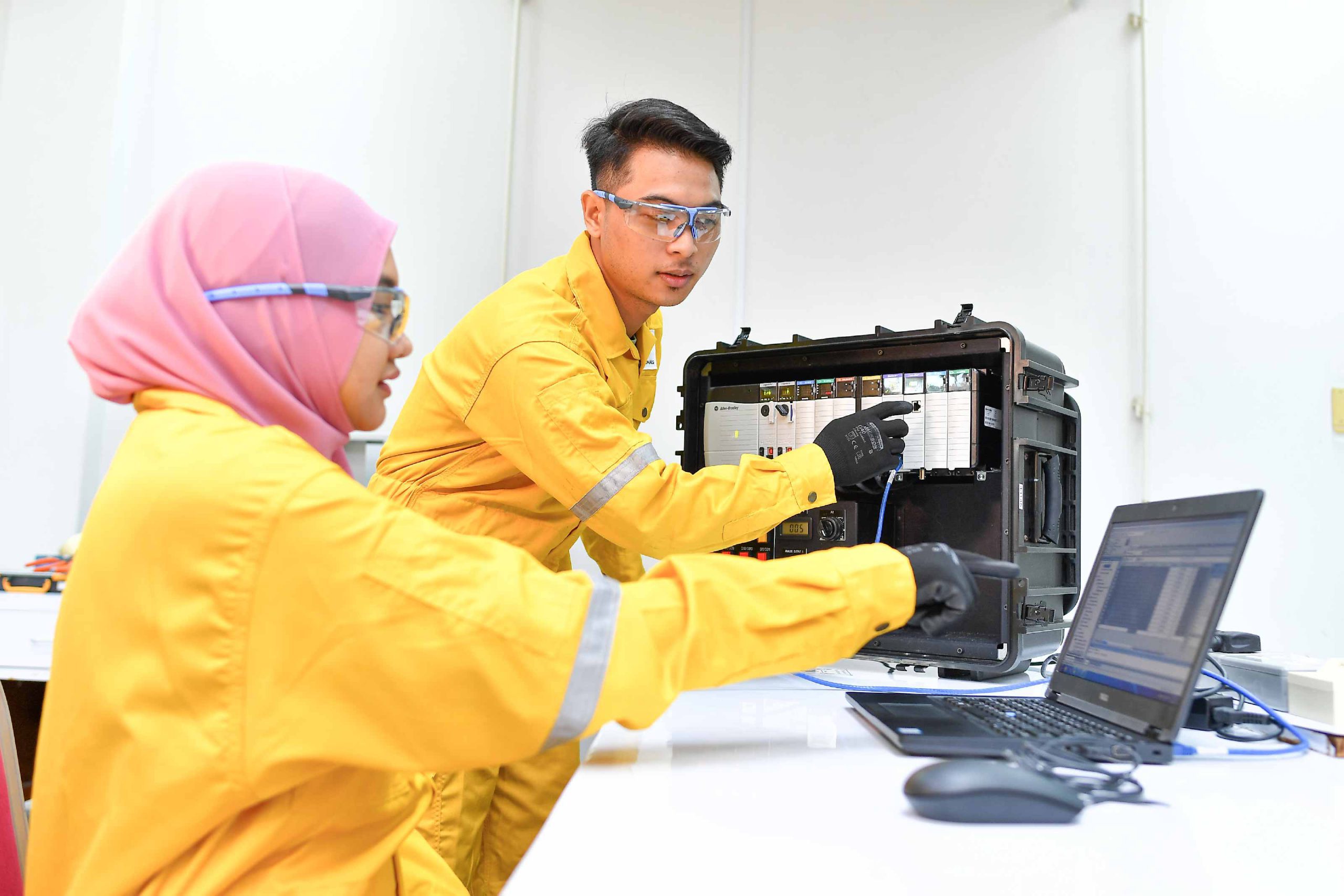

Programmable Logic Controller (PLC) Lab

This facility is equipped with Allen Bradley PLC5 and Control Logix 5000, as well as Level Control Training Simulators that will enable our learners to develop and enhance their knowledge and skills in programming, troubleshooting, and maintenance of automation system.

Liquid and Gas Metering

This programme provides basic understanding of liquid & gas metering system and its applications based on several metering installations in oil & gas industry.

It mainly focuses on metering operation practices in petroleum industry with emphasis on custody metering.

At the end of this programme, participant will be able to:

- Explain the working principle of the volumetric flowmeter

- Perform metering equipment maintenance and validation

- Perform volumetric flowmeter proving

Introduction to the Distributed Control System (DCS) Operation - Yokogama CS3000 for Process Operator

This programme is designed to develop participants’ knowledge, skills and competency to perform the roles of a process operator involving Distributed Control System (DCS) Operation for Yokogama CS3000.

At the end of this programme, participant will be able to:

- Identify the major components of DCS System Architecture

- Describe and operate the HIS essential functions and interpret the system messages

- Describe the basic control loop and control strategy used in CS3000

- Describe and interpret the process & system alarm in CS3000

- Describe the trend functionality and structure of report in CS3000

Certified Personnel for Metering Validation and Calibration Competency Programme

This is a 5-days competency programme which provides knowledge and skills to participants to become certified personnel for metering validation and calibration.

At the end of this programme, participant will be able to:

- Perform metering validation and calibration activities in accordance with the procedures and standards

- Be certified competent personnel who perform metering validation and calibration activities

Instrument Installation and Maintenance

This is a 3-days programme which provides basic understanding to participants about instrument installation and maintenance.

At the end of this programme, participant will be able to:

- Describe various aspect and drawings of Instrument Installation

- Explain the basic knowledge of cabling and tubing works

- Aware of common mistakes made during installation & maintenance

Liquid Metering Training Skid

This facility is equipped with various types of flowmeters such as Ultrasonic, Coriolis, and Turbine Flowmeter which are completed with prover, station computer and flow computer that will enable our learners to develop and enhance their knowledge and skills in operation of metering skid, validation of field instruments, and meter proving.

Distributed Control System (DCS) Lab

This facility is equipped with Honeywell and Yokogawa DCS System which are integrated with process mini plants.

It enables the learners to develop and enhance their knowledge and skills in performing operation and control of the process mini plants, as well as maintenance and engineering activities on the control system.

Additionally, this facility is also equipped with Operator Training Simulator (OTS) which enables our learners to develop skills as a Panel Operator.

Process Control Lab

This facility is equipped with various models of mini plants that utilise air and water as the process medium. They can be integrated to form more complex plants. The Process Plants can be controlled either via Local Controller or DCS Programmable Logic Controller (PLC).

These enable our learners to develop and enhance their knowledge and skills in performing safe operation and control of the process mini plants, installation, and maintenance of field instruments.

Control Valve Workshop

This facility is equipped with various types of Control Valves ranging from pneumatic to SMART type Control Valve, which are completed with test and calibration equipment that will enable the learners to develop and enhance their knowledge and skills in performing testing, maintenance, and calibration of Control Valve.

Instrumented Safeguarding System Lab

This facility is equipped with Safety Instrumented System (SIS) and Fire and Gas System (FGS). These systems are fully integrated with DCS, Human Machine Interface (HMI), Motor Control Circuit (MCC), and others that replicate the real oil and gas plant/platform systems architecture and technologies. Both systems use TRICON TMR and Honeywell Safety Manager QMR safety programmable logic controller as the logic solver. These safety programmable logic controllers are linked to DCS and HMI via MODBUS communications in both serial and TCP/IP.

SIS is equipped with various types of sensors and final elements that are configured to execute the safety function of water level and flow in mini plant and SIS training skid. FGS, on the other hand, also uses various types of fire and gas detectors and actuators. All fire and gas detectors are fully equipped with testing and calibration tools.

These facilities enable our learners to develop and enhance their knowledge and skills in performing safe operation, maintenance, and calibration of SIS and FGS.

Analyser Lab

This facility is equipped with various types of online analysers, Gas Chromatograph and Vibration Monitoring System which enable the learners to develop and enhance their knowledge and skills in performing installation, maintenance, and calibration of Quality Measuring Instrument and Condition Monitoring System.

Measurement Lab

This facility is equipped with the field instruments such as sensors, transmitters, switches and other calibration tools which enable the learners to develop and enhance their knowledge and skills in performing installation, maintenance, and calibration of process measuring instrument.

Programmable Logic Controller (PLC) Lab

This facility is equipped with Allen Bradley PLC5 and Control Logix 5000, as well as Level Control Training Simulators that will enable our learners to develop and enhance their knowledge and skills in programming, troubleshooting, and maintenance of automation system.

Contact Us

Get in touch with us with any question or inquiry.

We are more than happy to chart your technical upskilling journey together with INSTEP.

Stay Connected with Us

Sign up for email updates and be the first to know of the latest developments from INSTEP.